Table Of Content

The Manufacturing Laminate Creation utility allows users to generate and organize manufacturing data early in the development process, concurrent to the design engineering phase. For example, engineering software from Siemens NX and CATIA from Dassault Systèmes enables the simulation of machining, casting and shaping, among other industrial processes. Engineers and product designers using a DFM approach by collaborating in a modern office. Corrosion-resistant composite materials, i.e. pultruded products, are replacing the old paradigm of what offshore oil rigs once looked like. In addition, it cuts costs by reducing the time and labor needed to make parts. Furthermore, DFM increases the possibilities for automation by reducing the need for manufacturing oversight.

3D Printing

DFM is usually used to reduce these costs.[1] For example, if a process may be done automatically by machines (i.e. SMT component placement and soldering), such process is likely to be cheaper than doing so by hand. Leveraging product lifecycle management (PLM) software helps a business source and compare potential suppliers based on sustainability request-for-proposal (RFP) requirements. Doing so not only takes available information about suppliers into account, but also adds further information to your digital enterprise from supplier logistic network simulations. Did you know 80% of a product’s environmental impact is determined in the design phase? With so much dependence on design, it is critical to start thinking about the environmental impact of a product as early as possible, alongside the traditional drivers of cost, quality, and time. Surrogate parts are placeholder parts used to assess specific functional aspects of a design and tune in the final manufacturing process before mass production.

Manufacturing process

In particular, processes like surface-mount technology (SMT) and soldering are becoming more automated, generally lowering costs over the long term. DFMA applies these techniques to a company’s standard production line to create a product that is easy to manufacture and assemble. It may use integrated product development disciplines such as concurrent engineering to bring down costs and improve product reliability. As most of the design and manufacturing issues are addressed in the early stages of the design process, fewer issues crop up during the actual manufacturing process.

Semiconductor design and manufacturing - Siemens

Semiconductor design and manufacturing.

Posted: Wed, 27 Mar 2024 08:54:04 GMT [source]

Case Study 1: Automotive Industry

Opting for a more straightforward manufacturing technique, such as injection molding, rather than CNC machining can lead to reduced production costs but less design flexibility. However, choosing a more specialized material with better qualities can raise material prices and lead times. To further aid in problem identification and parameter optimization for effective production, process simulation tools mimic machining, casting and forming operations. In the end, these tools help engineers optimize designs, anticipate performance and evaluate manufacturability.

Design for Manufacturing (DFM): The Ultimate Guide to Streamlining Product Development and Reducing Costs

Decreasing the number of parts in a product is the quickest method to save costs since you are reducing the quantity of material necessary and the amount of engineering, manufacturing, labor, and shipping expenses. Design for Manufacture and Assembly consists of two primary methodologies. DFM and DFA aim to optimise design while lowering labour, materials, and overhead costs. The book Computer-Aided Manufacturing offers 10 generally accepted Design for Manufacturing principles that were developed to help designers decrease the cost of and complexity of manufacturing a product.

Streamlined product development process

Sanyo Seisakusho: Pioneering excellence in mold design and manufacturing - The Worldfolio

Sanyo Seisakusho: Pioneering excellence in mold design and manufacturing.

Posted: Tue, 30 Jan 2024 08:00:00 GMT [source]

The quality of products and their ability to meet customer requests will be even better thanks to these innovations, which will allow for automated decision-making, real-time monitoring and predictive analytics. Adjustments guided by DFM also made ejection better by making sure the molded product came out of the mold more uniformly. Adding ejection surfaces to the rib connection points significantly improved the part's reliability and manufacturability. This case study shows how important design in manufacturing is for improving electronics manufacturing efficiency and component design.

What are the best tools to use for DFM?

Both approaches should be considered and implemented to ensure that a product is designed and manufactured efficiently and effectively. Computational Fluid Dynamics (CFD) evaluates fluid flow and heat transport with the goal of developing better cooling systems and fluid-based manufacturing processes. With Moldflow Analysis, you can optimize your component design and mold setup for injection molding.

THE DANGER OF TIGHT TOLERANCES IN DFM

One of the most significant obstacles to DFM implementation is resistance to change. Implementing DFM requires a shift in mindset from designing products based solely on form and function to designing products with manufacturing in mind. This can be a significant change for design teams, who may be used to working independently of manufacturing teams. There are various software and tools available that can aid in DFM analysis. These tools can evaluate a design's manufacturability, identify potential manufacturing issues, and suggest design improvements.

This form of optimization can be incredibly advanced when using computer-aided design (CAD) software that integrates DFM analysis capabilities. Naturally, the time taken for any process will depend on the product, parts, manufacturing process, and the complexity of operations required. However, on average, a DFM process will take around two weeks to complete. This number may increase to three or even four weeks for more complex products. On one hand, design and manufacturing teams need to communicate their requirements, constraints, and goals to the supplier clearly. On the other hand, suppliers should be proactive in sharing their expertise and offering constructive feedback on the proposed designs.

Ideally, DFM guidelines take into account the processes and capabilities of the manufacturing industry. While DFM is applicable to the design process, a similar concept called DFSS (design for Six Sigma) is also practiced in many organizations. Airbus is confident that a planned A350 production rate hike to 12 aircraft monthly can be accommodated both by the supply chain and the airframer’s own industrial system. Ever wonder exactly why materials like marble and terrazzo tile are so in right now? And now, the Brooklyn-based studio is partnering with In The Pursuit to spread its gilded stone look.

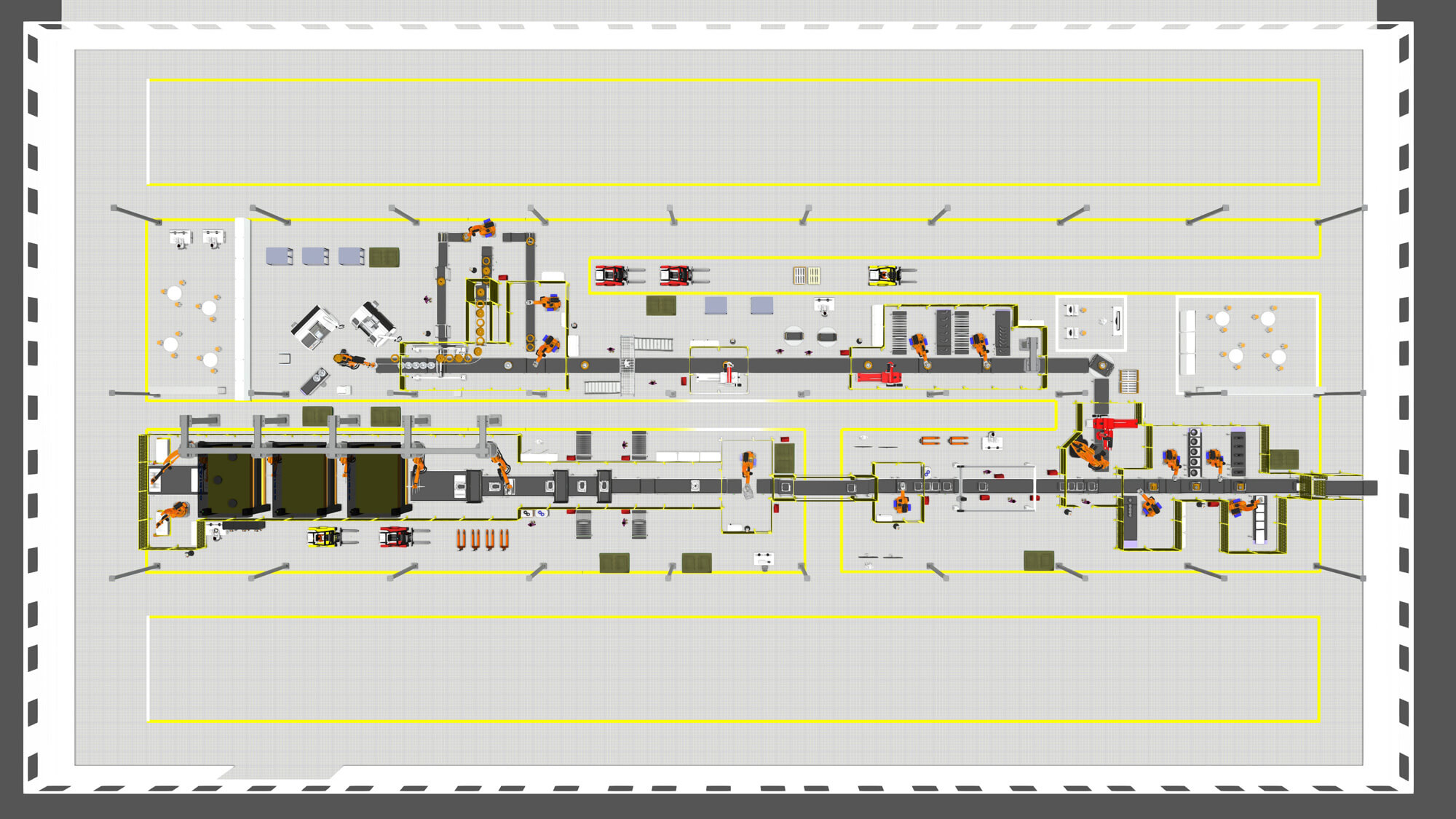

As a result they were able to move the same volume of cargo with fewer vehicles, reducing emissions by 22 percent and increasing their efficiency by 10 percent. Designers can print multiple mold iterations at a fraction of the cost and time to produce machined tooling. Read on to learn about DFM rules and principles for common manufacturing methods and the various ways 3D printing is used in manufacturing. To generate in depth DFM insights, there is no substitute for detailed digital manufacturing simulation.

No comments:

Post a Comment